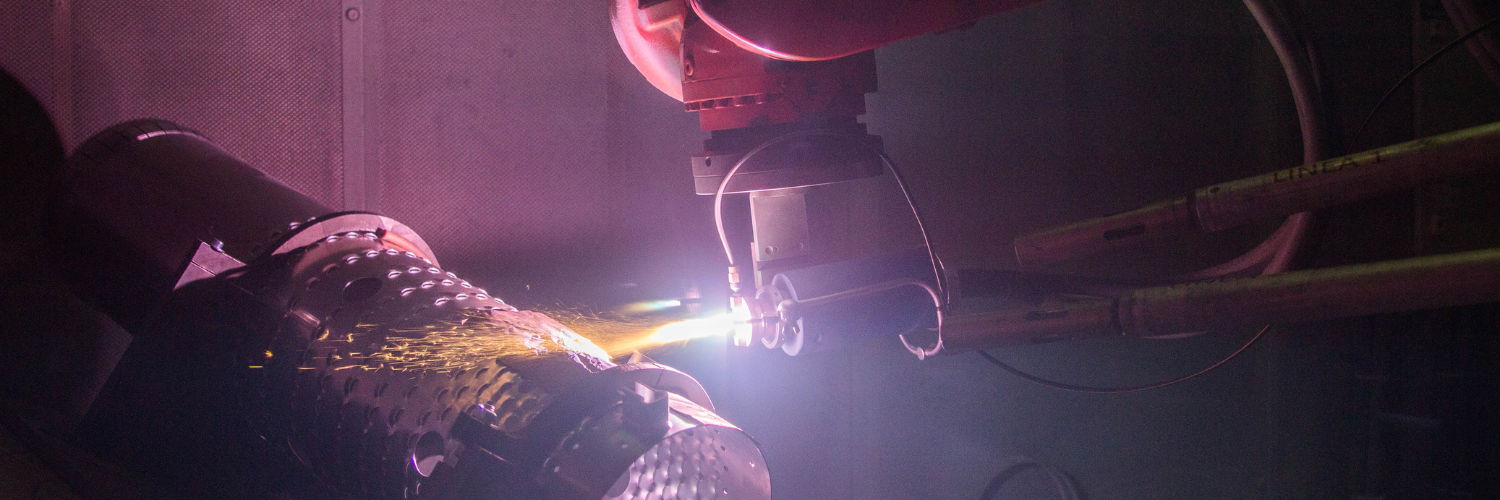

HVOF (High Velocity Oxy Fuel) Coating and Grinding

The HVOF (High Velocity Oxy Fuel) process consists of an internal combustion process that generates a supersonic jet for heating and accelerating the powders towards the part to be coated; once the substrate is impacted, the powder droplets quickly solidify, and produce, due to their high kinetic energy, lamellar structures.

The HVOF process allows, at sustainable costs, to improve the surface properties of the part and thus to extend its life, even in particularly corrosive and wearing work environments. Generally, this result can be obtained without interfering with the mechanical and structural characteristics of the substrate and therefore without the need for further treatments.

The HVOF process allows to apply high-density coatings, characterized by high hardness and high adhesion to the substrate and a better surface finish than other thermal spraying processes.

The thicknesses of the HVOF sprayed coatings vary from 50 to 500 µm. The surface finish in the “as-sprayed” condition is generally higher than 2.5 µm (Ra). The coatings can be used in the “as-sprayed” condition or subjected to a final grinding and lapping to meet customer requirements.

HVOF sprayed coatings of chromium or chromium-carbides can be used as an alternative to hard chromium plating to provide protection from wear and corrosion.

Advantages

- High wear resistance due to the greater hardness and compactness of the coating

- High hardness due to the lower degradation of the carbides

- High resistance to corrosion due to the low internal porosity

- High density (low porosity) of the coating due to the impact speed of the particles

- High adhesion of the coatings to the substrate material and high internal cohesion of the coating

- Reduced oxide content due to shorter time in flight of the particles (lower exposure to oxygen)

- Better surface finish of the “raw” coating due to the high impact speeds and lower particle size of the powder

- Alternative to chrome plating process

Applications

Aerospace

- Components of the engine

- Components and actuation systems

Energy (gas turbines)

- Combustion chambers

- Nozzles

- Injectors

- Burners

- Liner and Cap Liner

- Transition pieces

- Cooling pipes

- Sectors of stator rings

Materials

- Alloy steels

- Stainless steels (austenitic and martensitic)

- Nickel and Cobalt based superalloys